SHOPPING CART

0

0

Item - 0,00 €

Items - 0,00 €

No items - 0,00 €

No products

Delivery Ex Works Italy

Shipping

0,00 €

Total

Product successfully added to your shopping cart

Quantity

There are 0 items in your cart. There is 1 item in your cart.

Total products + Packing cost

Total shipping

Delivery Ex Works Italy

Total

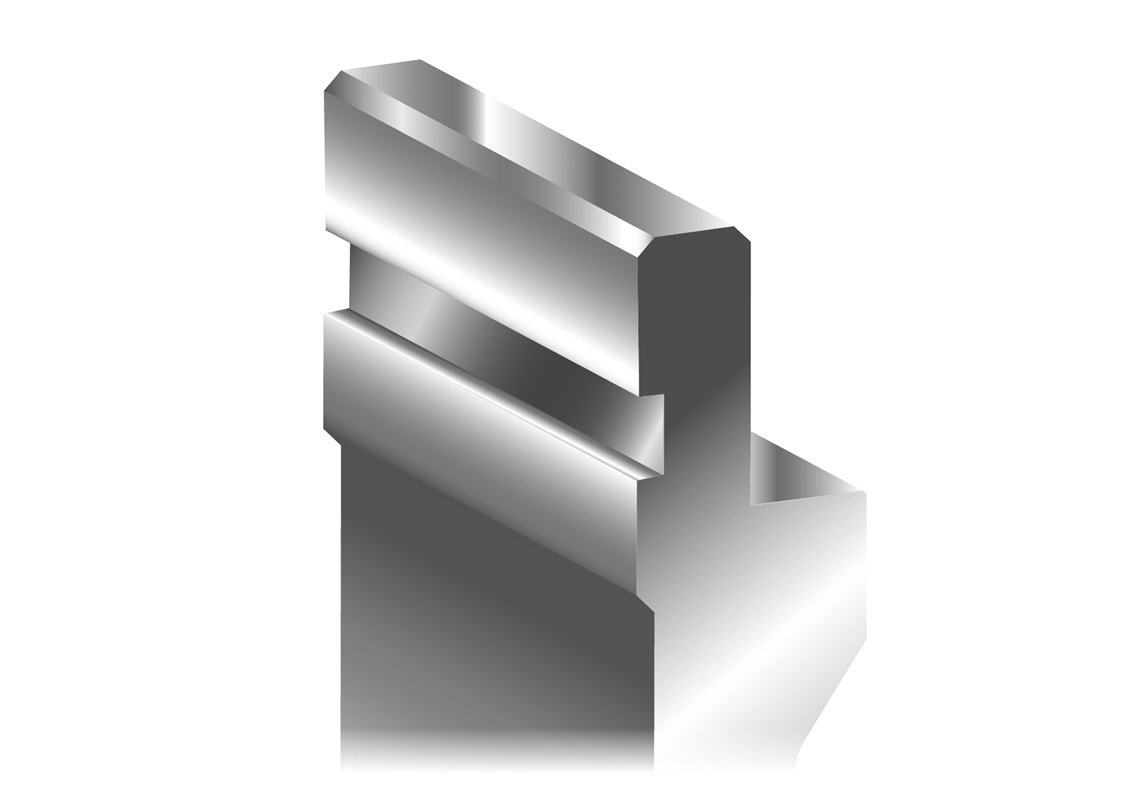

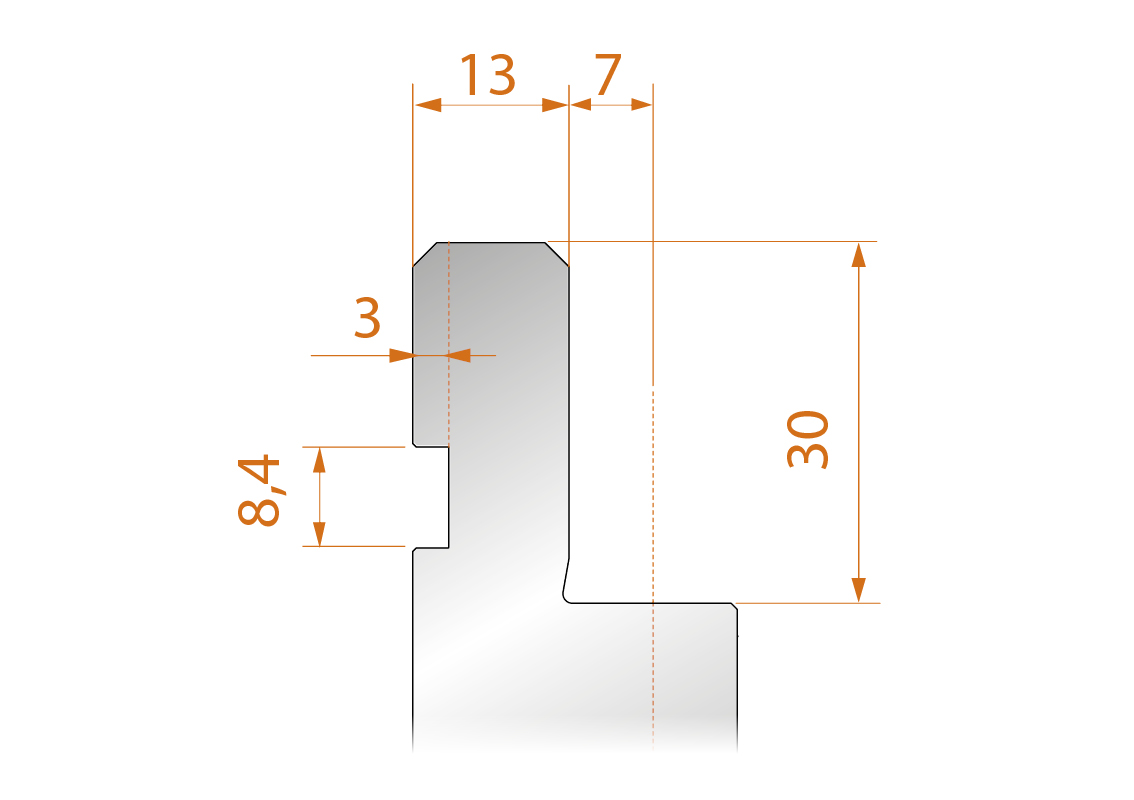

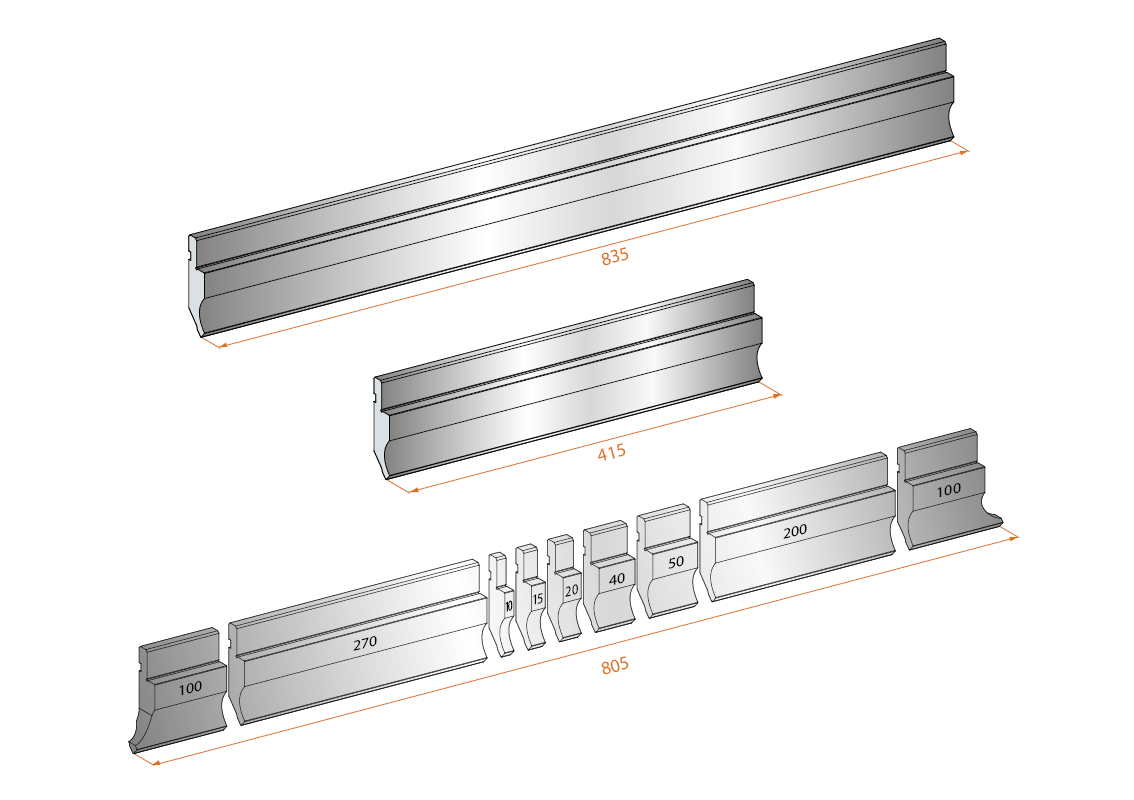

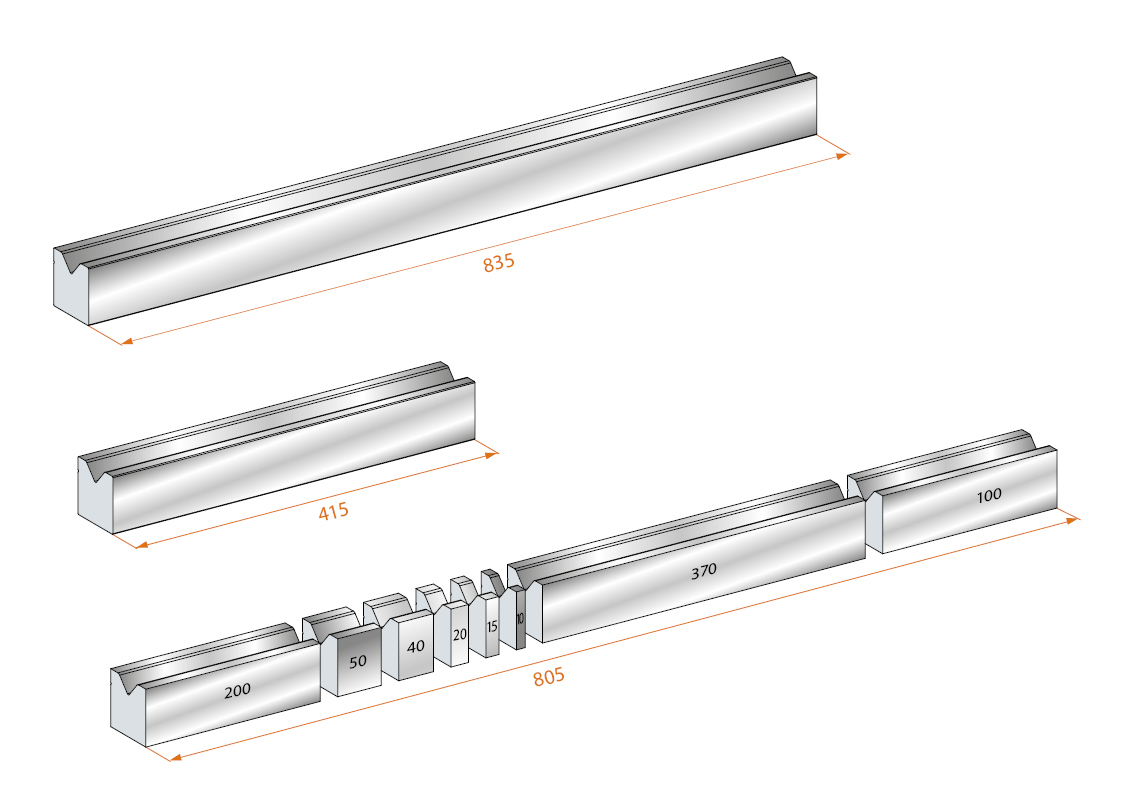

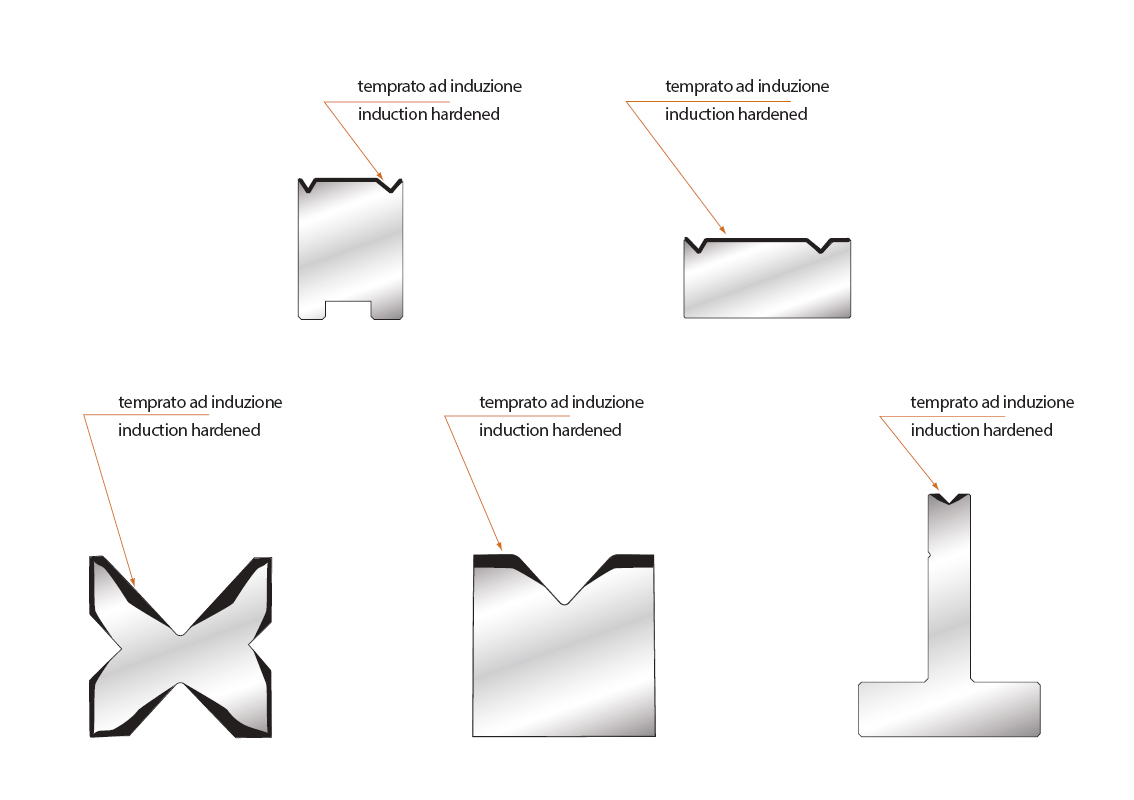

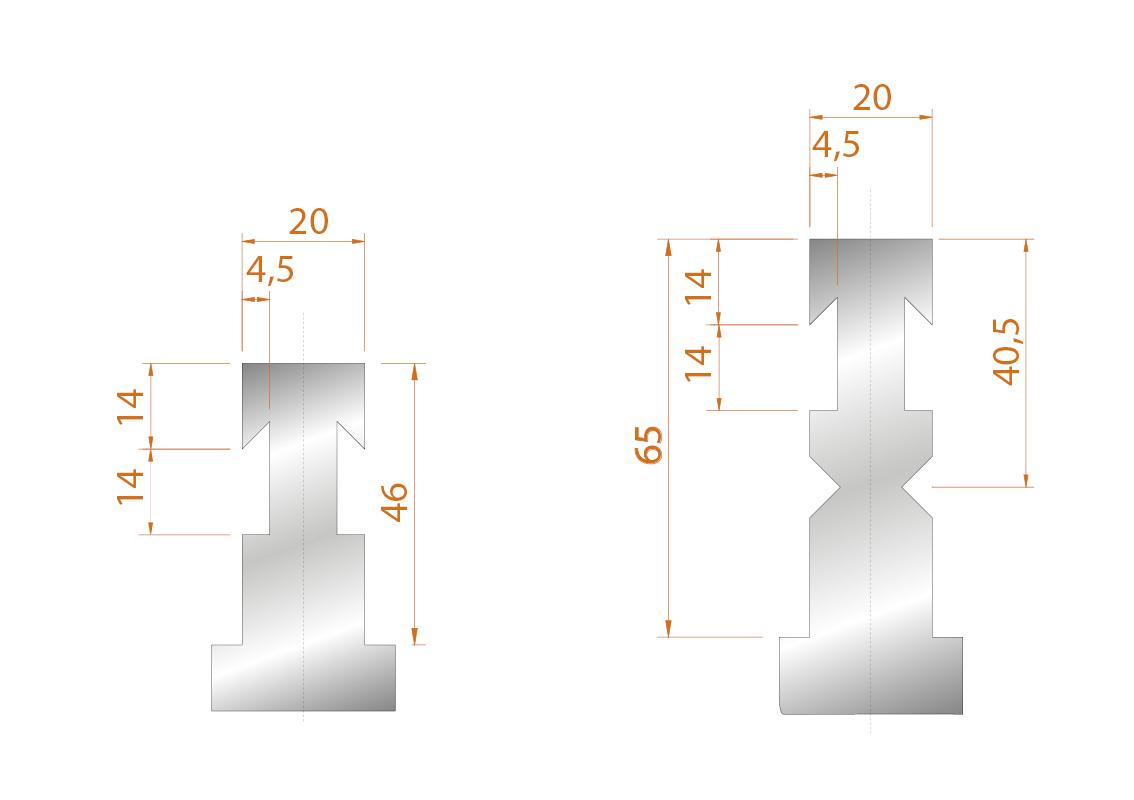

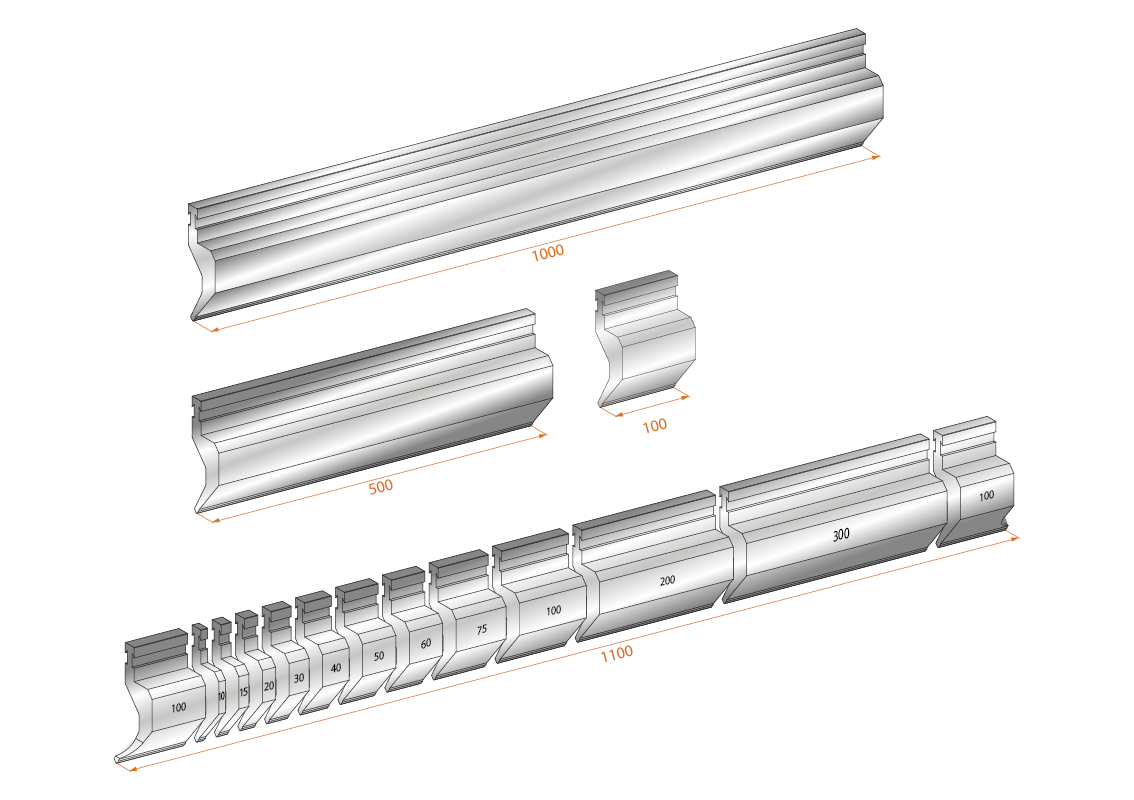

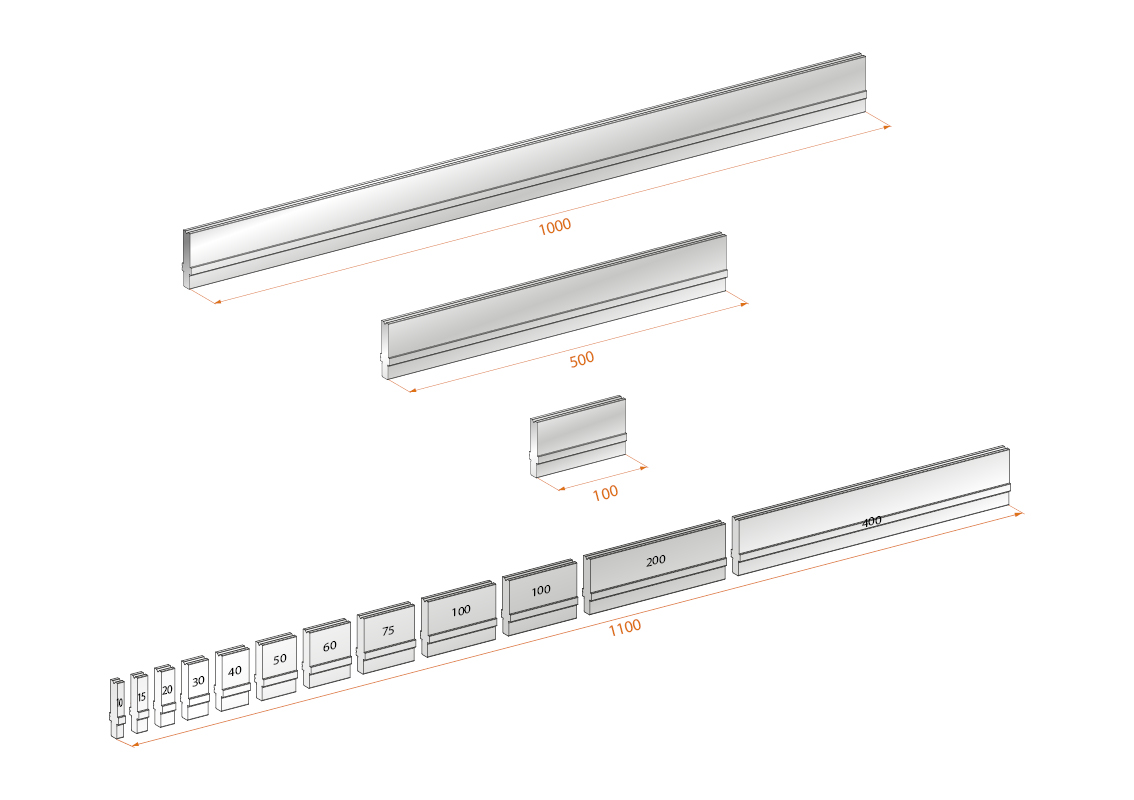

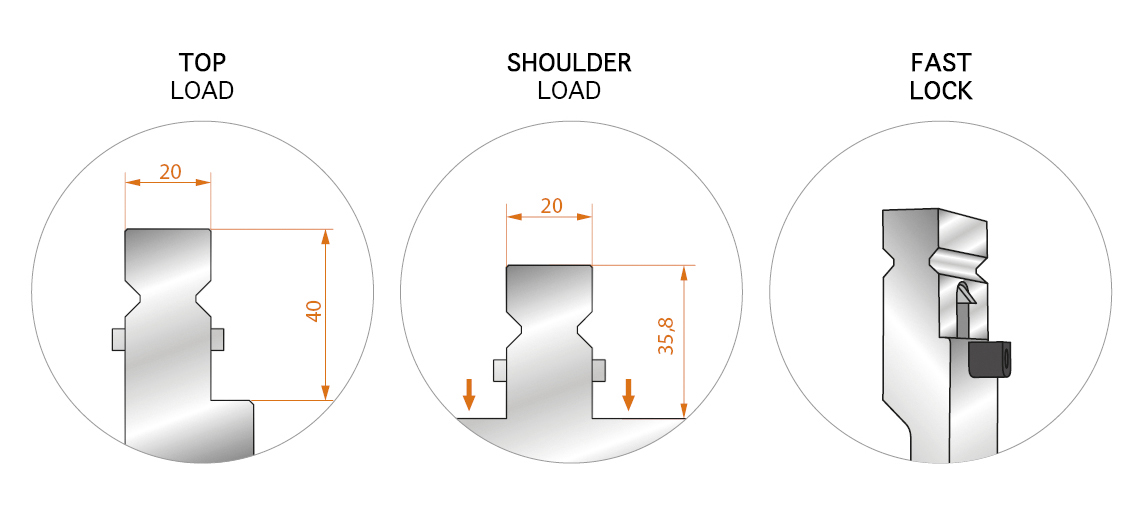

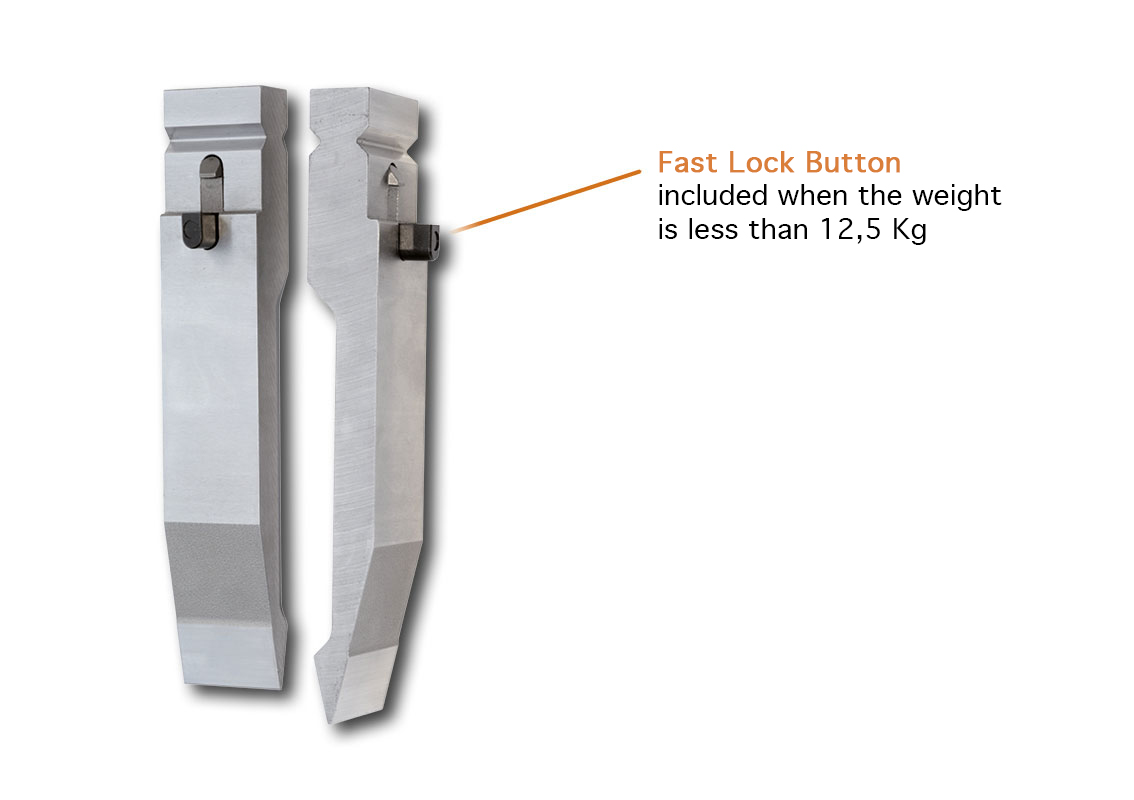

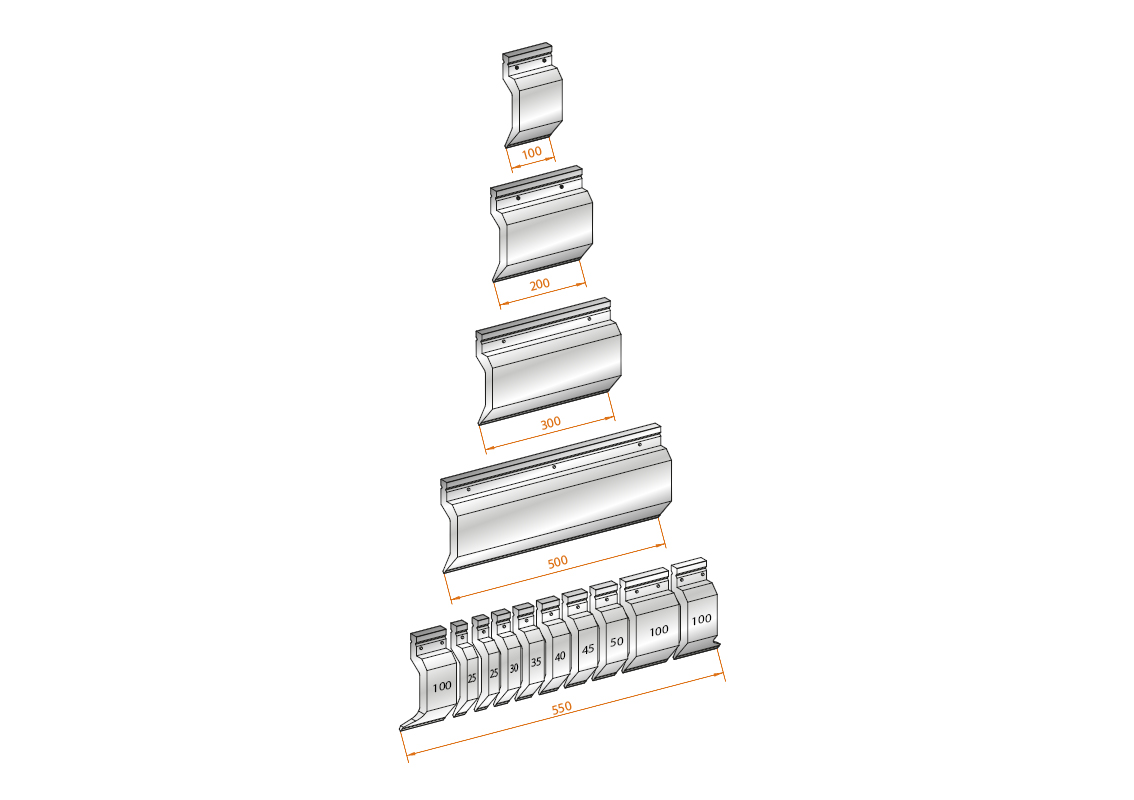

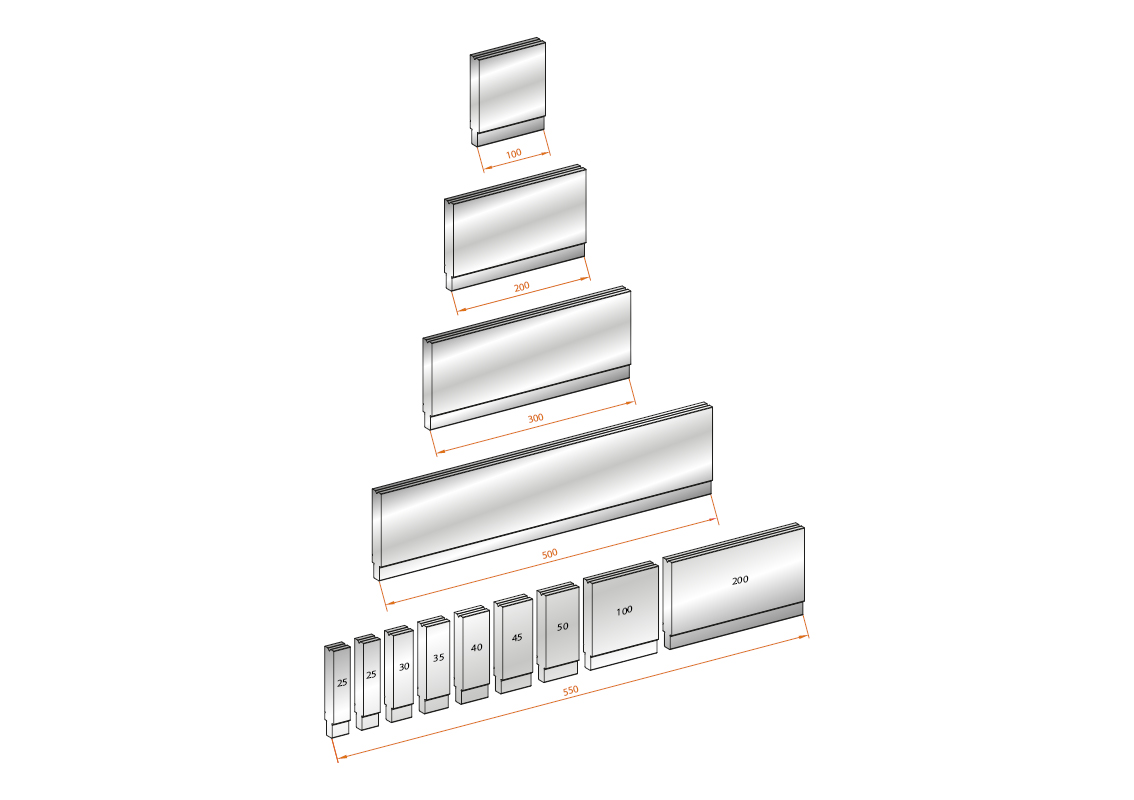

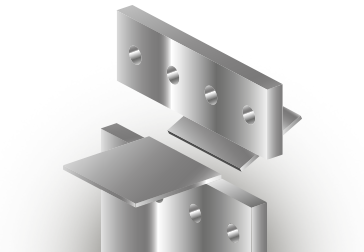

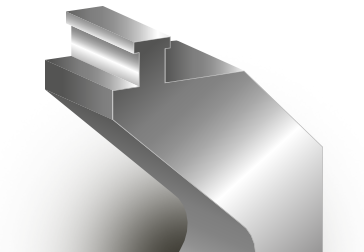

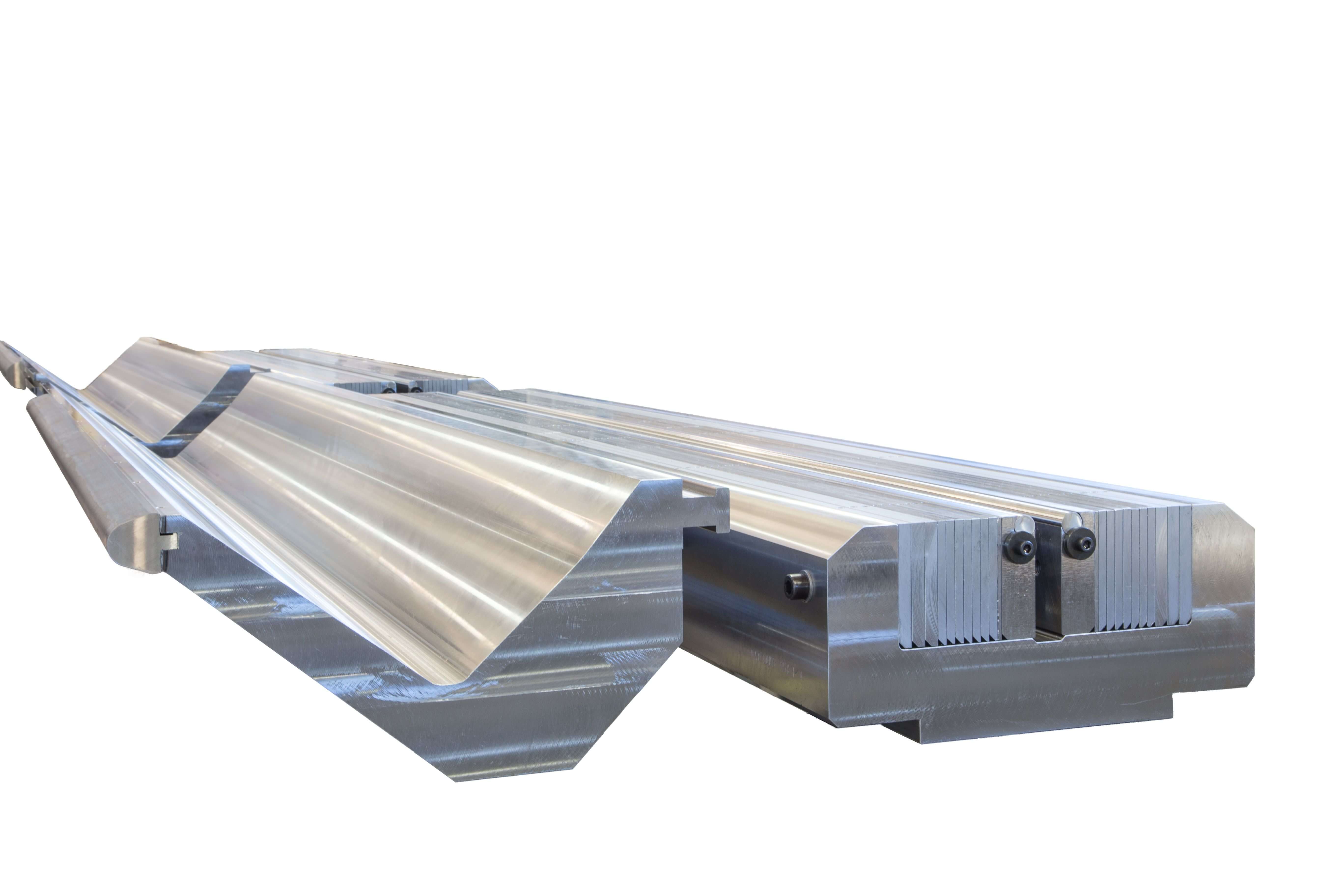

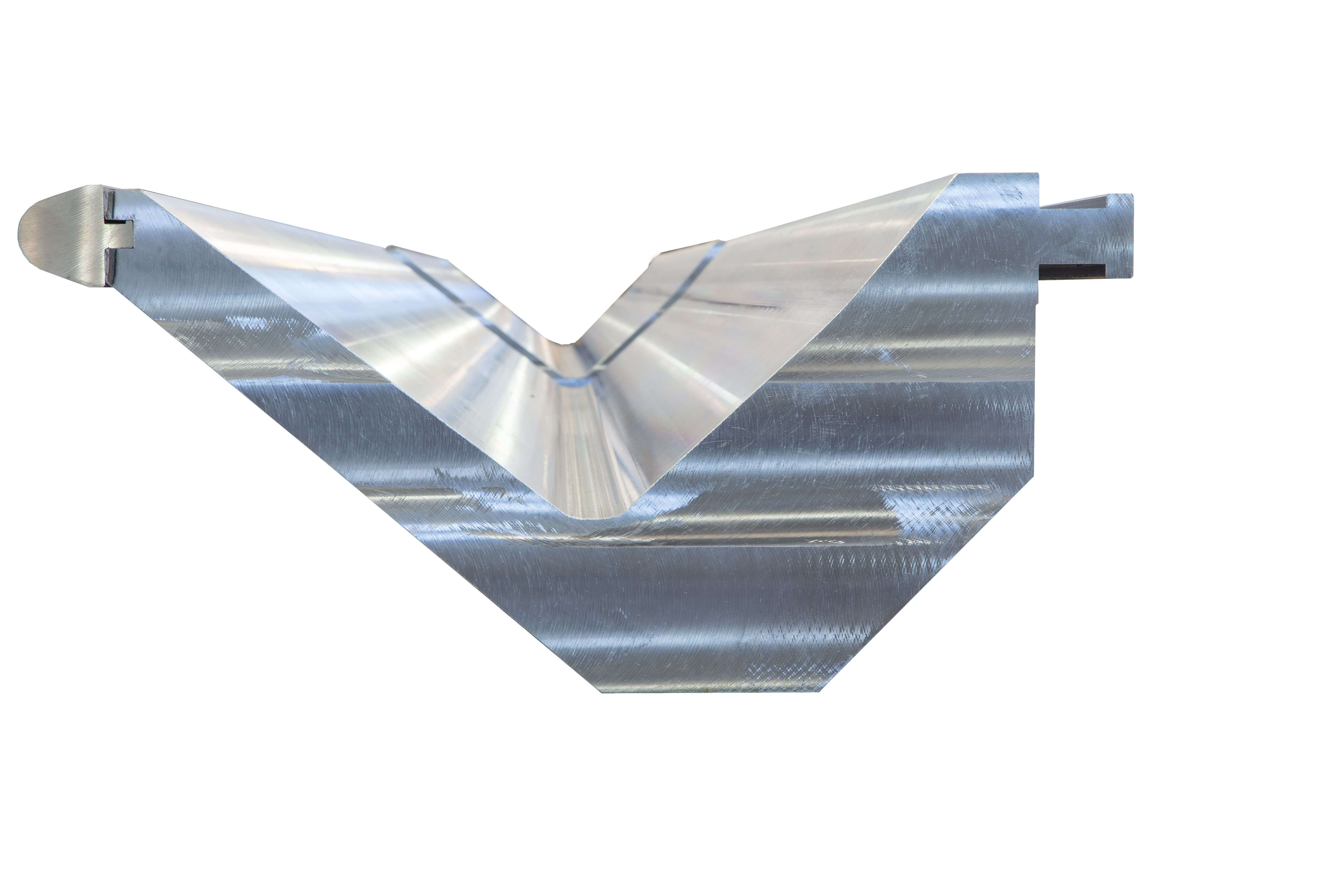

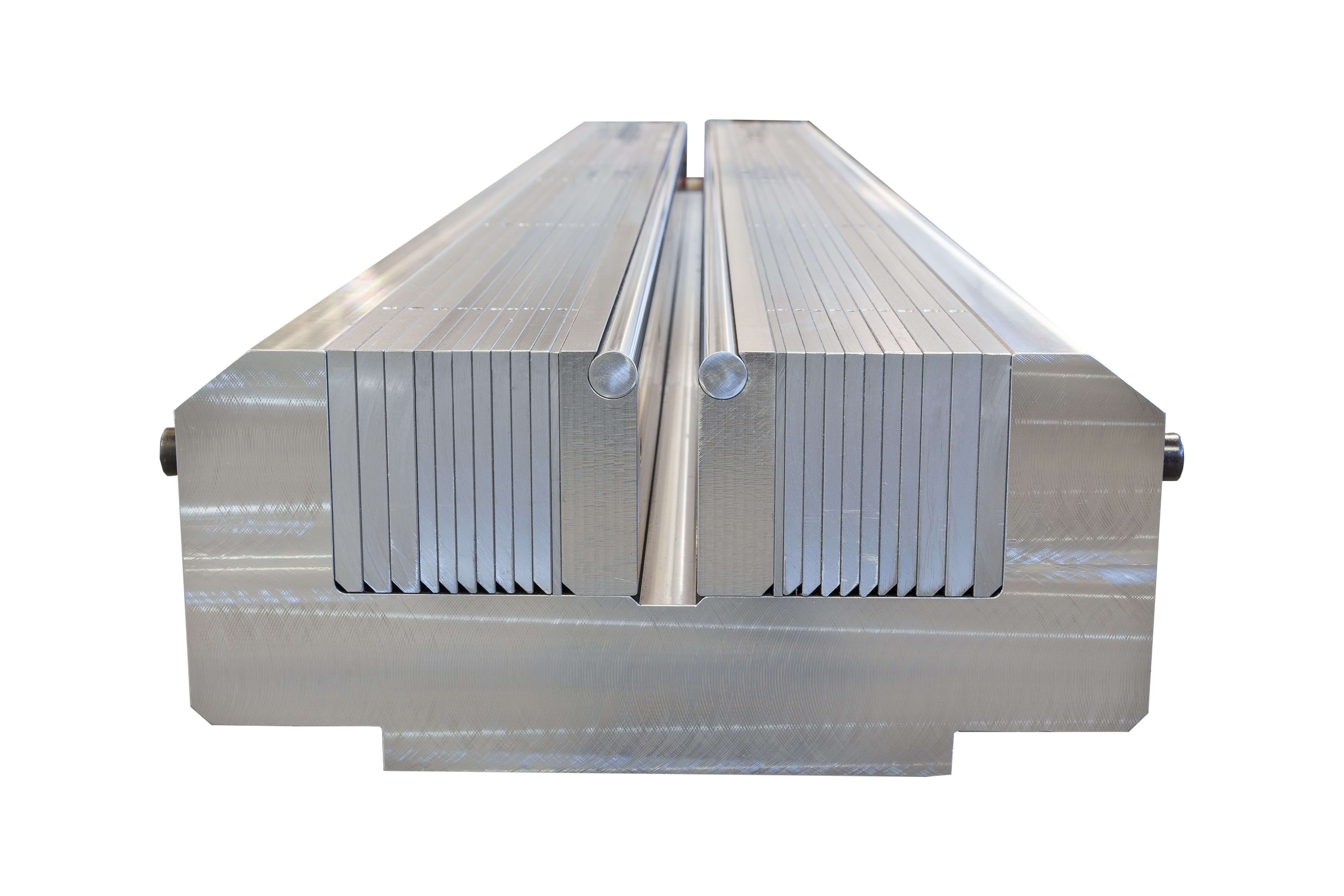

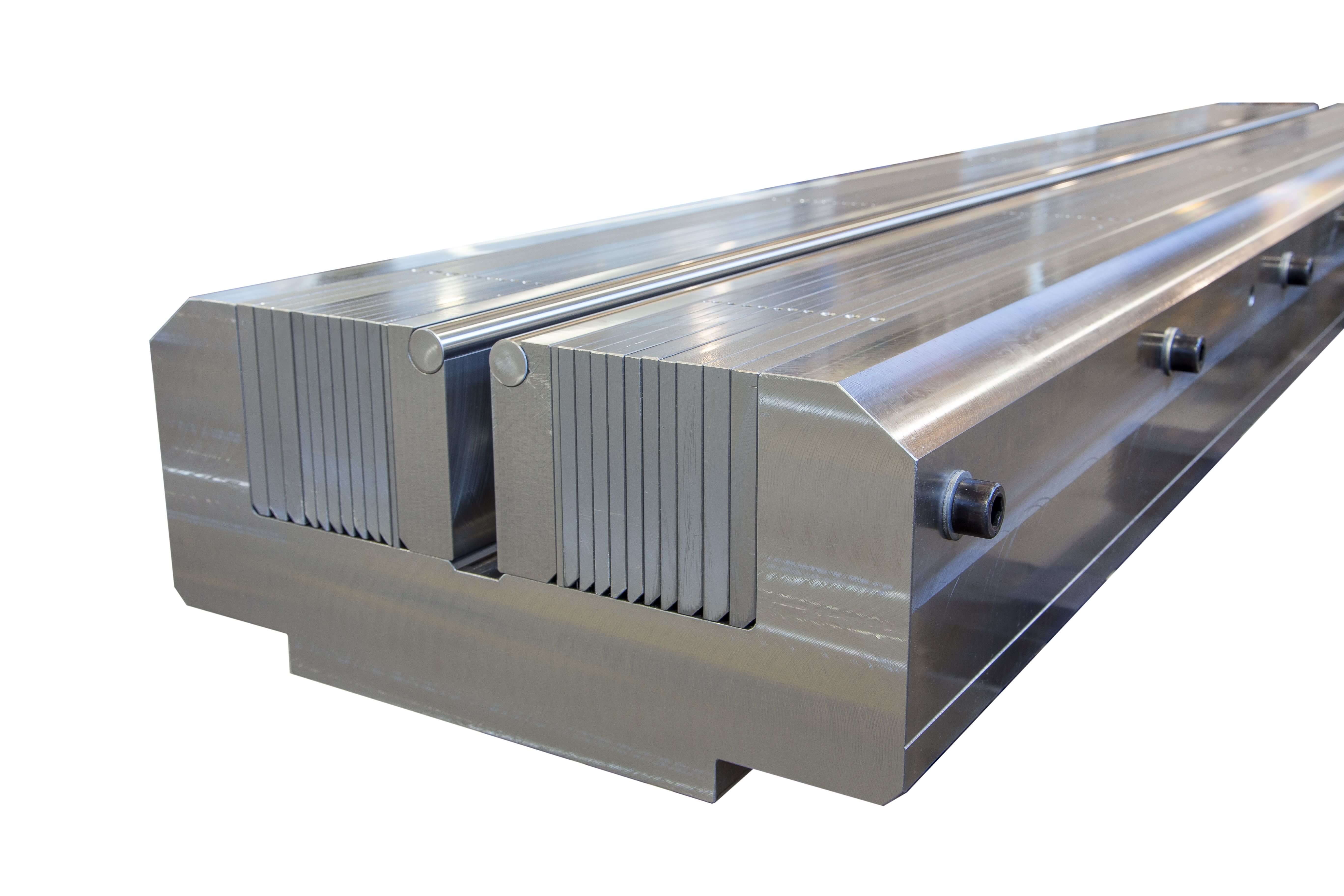

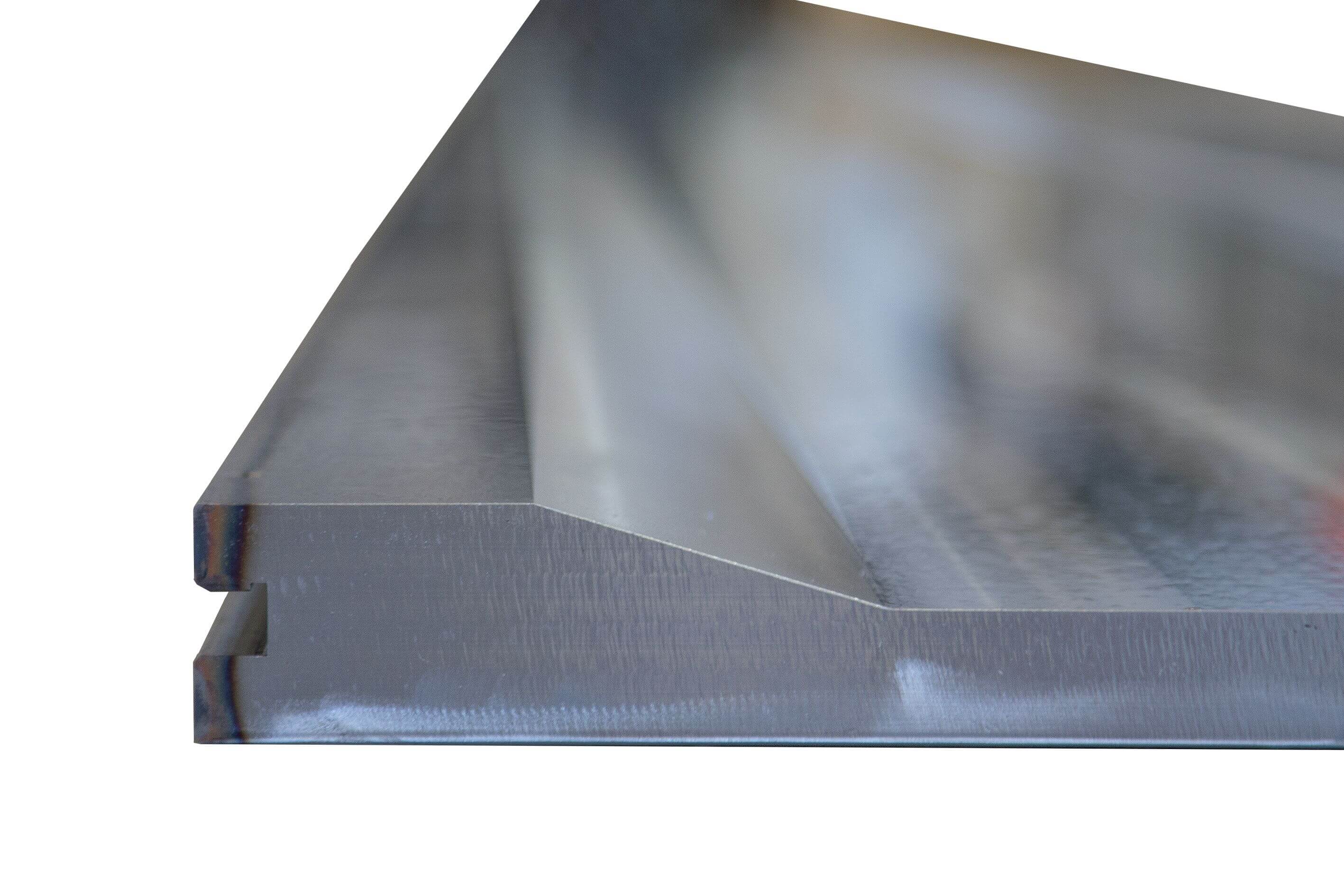

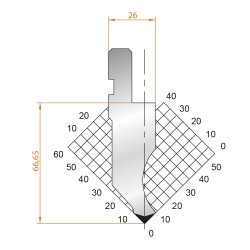

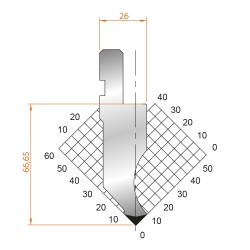

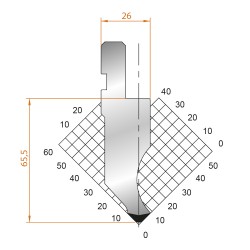

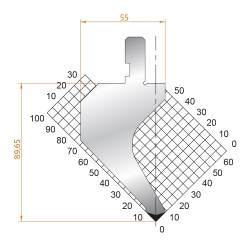

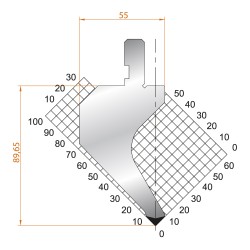

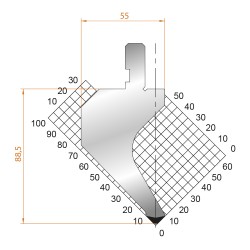

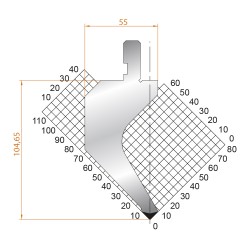

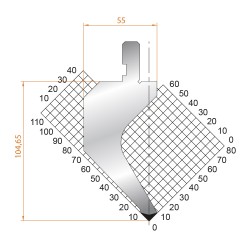

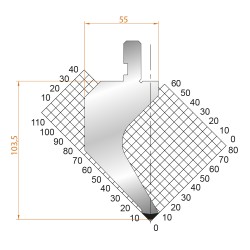

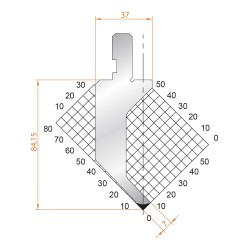

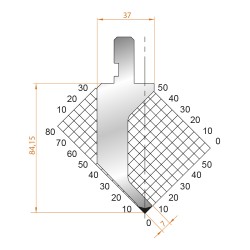

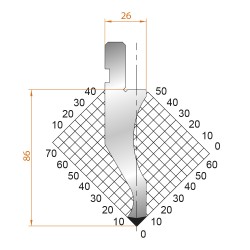

Bystronic type

High strength tools